Home Blog Product Info Shore Hire’s Range of Modular Props

Modular props are known in the construction industry for being some of the most popular propping solutions available, due to their capacity, flexibility, and ability to be used in a much larger range of applications than more common building props would.

What Are Modular Props?

Our Shore Prop 100, 200, 400, and 1000 are highly flexible, high-load-bearing solutions for propping in horizontal, vertical, and raking applications, meeting the high demands of today’s competitive construction industry.

They are fabricated steel posts that are made from two “C Section” pieces that are construction with welded top and bottom places as well as intermediate spacer plates.

Our modular props can be assembled by connecting sections of various sizes to achieve the required height or length.

Shore Hire’s range of modular props includes:

- Shore Prop 100: Our Shore Prop 100 is lightweight, striking a balance between minimising component weight to reduce manual handling risk and maintaining robustness and load capacity.

- Shore Prop 200: The Shore Prop 200 is an integral part of our modular propping range, providing a remarkably flexible and robust solution for propping in both horizontal and vertical applications.

- Shore Prop 400: Aimed at the building refurbishment market, the Shore Prop 400 has quickly developed into a multi-purpose propping system, used extensively in both the civil and building industries.

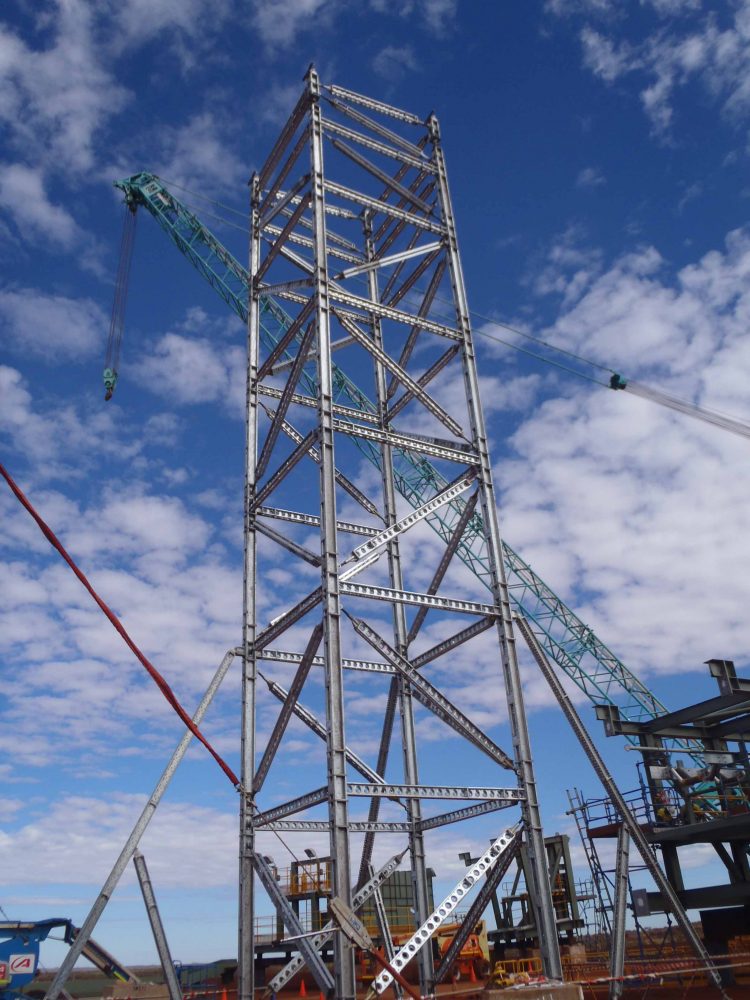

- Shore Prop 1000: The main strength of our Shore Prop 1000 is its rigid and robust construction and versatility, which make it ideally suited for heavy-duty back propping, temporary bridge propping, heavy-duty towers, and falsework.

What Are the Applications for Modular Props?

Our Shore Prop 100, 200, 400, and 1000 can be used in a large number of applications, but some of the most common are:

- Back Propping: Back propping refers to installing props vertically to spread force down to a solid base, such as a concrete slab. It’s incredibly important that when back propping a structure, there must be a solid base of concrete or timber sleepers to ensure the load is spread downwards to the base of the structure.

- Falsework: Falsework can be made from our modular props and is essentially temporary support to hold sections of concrete or concrete blocks in place until they have fully cured.

- Façade Retention: Façade retention refers to propping that is done to protect the façade of a building, often a heritage-listed one, while construction work is done on other parts of the property. Façade retention applications are often unique and require bespoke engineering, which requires multiple types of props.

- Modular Towers: Modular Towers are built to increase the capacity in order to place something on top, such as a bridge or bikeway. Our Shore Prop 1000s are often used with our Shore Prop 100 and 400, allowing for a wide configuration of towers and structures, minimising the need for fabricated steel structures.

- Needling: Needling is used to support or strengthen an existing structure while construction work is being done. Any of our modular props can be inserted through the structure and then onto whatever temporary propping system is used on either side to create a goal post-type setup.

- Underpinning: Building foundations can be underpinned with our modular props to help increase the building’s load-bearing capacity and ensure the foundation is supported.

- Bridge Propping: Bridge propping is when modular props are used to prop a bridge while it is being built, or during construction, maintenance, or repairs. Propping a bridge will almost always require heavy engineer involvement, as bridges are unique and can have dynamic loads.

What Are Some of the FFeatures of Modular Props?

Shore Hire’s modular props offer a number of features that benefit construction projects, including:

- Our Shore Prop 100, 200, 400, and 1000’s modular design allows for easy integration with each other, as well as a number of other Shore Hire products, enhancing their adaptability

- Their modular design and adjustable foot jacks mean that regardless of the dimensions of your project, Shore Hire can design an arrangement to suit

- Adjustment is at the end of the unit, which means that each modular prop will always remain in the strongest orientation, allowing ease of cross-bracing in multiple prop applications, and enabling swift adjustment to varying heights, ensuring a secure setup on every project

- To ensure they never rust or deteriorate, all of our modular props are hot dip galvanised

How Can Modular Props Be Installed?

All of our modular props can be installed by joining different-sized sections together and positioning Screw Jacks at either the top or bottom of the propping structure until it is slightly shorter than the desired height, standing the prop upright and positioning it under the load that needs to be supported, and rotating the adjustable collar with a spanner until the prop extends firmly under the load.

A prop’s required length may come from our range as a single section, or various lengths can be bolted together to form the required length. Sections are joined together with a minimum of four Grade 8.8 M20 bolts, nuts, or washers and can be bolted end-to-end, sometimes with the help of an ‘end connector’.

While our customers can install our modular props, our expert engineers and on-site rigging teams are equipped to handle the temporary works design, full installation, and dismantling of our modular props.

If you would like to learn more about our range of modular props or any of our other propping products, visit your nearest branch, email [email protected], or call our friendly team of experts at 1300 746 734.